SingletotalweightT18DailygarbagedisposalcapacityT80Theworkinghoursare8hours*theoverallsizeoftheequipmentismm7500*3000*1700

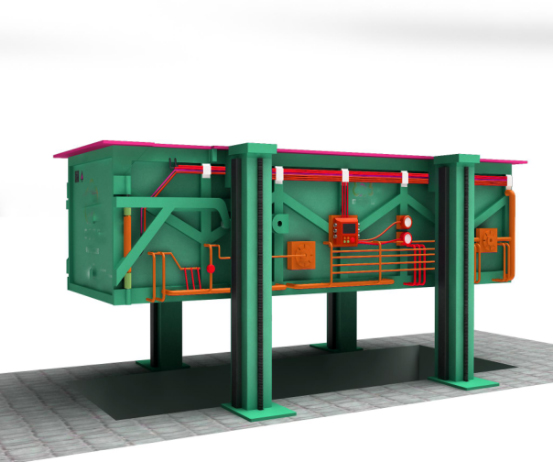

Main technical indicators:

Single total weight T 18

Daily garbage disposal capacity T 80

The working hours are 8 hours

* the overall size of the equipment is mm 7500 * 3000 * 1700

* garbage block size mm 3900 * 2050 * 1500

* the effective volume m3 of the compression chamber is greater than 12

Maximum compaction density t/m3 0.9

Weight of garbage block T 7 ~ 9

* feeding port size m 2.10 x 1.10

Operating voltage V 380 three-phase ac

* supporting motor power kw 15

Working pressure Mpa 16 ~ 21

Compression device:

Rated minimum compression force T 66

Maximum stroke of compression cylinder mm 4500

Lifting device

Rated minimum compression force T 66

Maximum stroke of compression cylinder mm 4500

Sewage pump

Power 2.2 kW or more

Lift m 10 or higher

Cleaning machine

Work rate kW 2.2 or higher

Working pressure Mpa 6-9

Theoretical flow L/min 20

Other requirements

Need to have automatic shutdown function

Performance configuration:

(1) garbage compression box must be integrated: that is, the compression bin, unloading bin, shovel-placed bin even as one, the whole

Fall to the ground;

(2) the front door of the box body shall adopt an oil cylinder to control the turning and tightening structure to improve the reliability; Lifting mechanism should be

It adopts the form of hydraulic vertical balance lifting with four upright columns. The four lifting columns should be matched with inner and outer columns and adopt high strength

Rectangular tube composition (thickness 8mm), to improve the stability of equipment and equipment overall safety;

(3) the inlet shall adopt the automatic closing structure of the inlet door to ensure the safety of the equipment and prevent garbage and odor escape

;

(4) the discharge door should be in the form of rotating folding door and transfer vehicle structure, and the compression shovel with the form of forward, to ensure better docking and separation of equipment and transfer vehicles;

(5) the thickness of the garbage compression box steel plate is not less than 8 mm, and the service life of the box is not less than 5 years;

(6) the control system adopts automatic and manual modes, that is, when the system fails, manual operation can be adopted to continue the work without affecting the compressed garbage;

(7) of the hydraulic system, hydraulic station and press with high pressure hose and seamless steel tube connection, and into the ditch or buried, layout reasonable, beautiful, hydraulic system work in a row after 45 minutes, the fuel tank of the oil temperature does not exceed 65 ℃, the hydraulic system consists of two sets of oil pump motor drive system, pressure head can realize fast forward, slow compression, and for the holding.

(8) there should be fixed operation cabinet, touch screen (with equipment self-inspection and error warning function) and three operating modes of small control panel for close operation of the equipment to facilitate operators to observe the operating equipment nearby (9) there should be no less than 30mA leakage protection device to ensure the safety of equipment and people;

(10) the control system shall operate at a safe voltage of 24V;

(11) the control system should adopt the industrial control safety interlock protection function, the front door of the equipment box should not be opened before the ground, to prevent the fault caused by the wrong operation; PLC control system, programmable operation, each action can be run independently, and individual actions interlock

(12) at the feeding port, there should be a fence to prevent garbage from being scattered outside the feeding port;

(13) 8mm patterned steel plate shall be used on the upper part of the box to meet the requirements of the large collection vehicle for feeding;

(14) with plasma physical air disinfection, deodorization system and sewage disinfection, deodorization purification system;

(15) sewage discharge system: there is an automatic sewage discharge system

(16) mechanical insurance system: there is a bumper device at the bottom of the box to prevent the box from falling down accidentally when cleaning the foundation pit

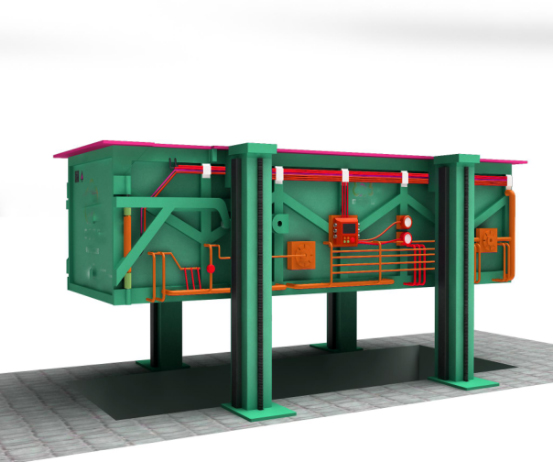

Main technical indicators:

Single total weight T 18

Daily garbage disposal capacity T 80

The working hours are 8 hours

* the overall size of the equipment is mm 7500 * 3000 * 1700

* garbage block size mm 3900 * 2050 * 1500

* the effective volume m3 of the compression chamber is greater than 12

Maximum compaction density t/m3 0.9

Weight of garbage block T 7 ~ 9

* feeding port size m 2.10 x 1.10

Operating voltage V 380 three-phase ac

* supporting motor power kw 15

Working pressure Mpa 16 ~ 21

Compression device:

Rated minimum compression force T 66

Maximum stroke of compression cylinder mm 4500

Lifting device

Rated minimum compression force T 66

Maximum stroke of compression cylinder mm 4500

Sewage pump

Power 2.2 kW or more

Lift m 10 or higher

Cleaning machine

Work rate kW 2.2 or higher

Working pressure Mpa 6-9

Theoretical flow L/min 20

Other requirements

Need to have automatic shutdown function

Performance configuration:

(1) garbage compression box must be integrated: that is, the compression bin, unloading bin, shovel-placed bin even as one, the whole

Fall to the ground;

(2) the front door of the box body shall adopt an oil cylinder to control the turning and tightening structure to improve the reliability; Lifting mechanism should be

It adopts the form of hydraulic vertical balance lifting with four upright columns. The four lifting columns should be matched with inner and outer columns and adopt high strength

Rectangular tube composition (thickness 8mm), to improve the stability of equipment and equipment overall safety;

(3) the inlet shall adopt the automatic closing structure of the inlet door to ensure the safety of the equipment and prevent garbage and odor escape

;

(4) the discharge door should be in the form of rotating folding door and transfer vehicle structure, and the compression shovel with the form of forward, to ensure better docking and separation of equipment and transfer vehicles;

(5) the thickness of the garbage compression box steel plate is not less than 8 mm, and the service life of the box is not less than 5 years;

(6) the control system adopts automatic and manual modes, that is, when the system fails, manual operation can be adopted to continue the work without affecting the compressed garbage;

(7) of the hydraulic system, hydraulic station and press with high pressure hose and seamless steel tube connection, and into the ditch or buried, layout reasonable, beautiful, hydraulic system work in a row after 45 minutes, the fuel tank of the oil temperature does not exceed 65 ℃, the hydraulic system consists of two sets of oil pump motor drive system, pressure head can realize fast forward, slow compression, and for the holding.

(8) there should be fixed operation cabinet, touch screen (with equipment self-inspection and error warning function) and three operating modes of small control panel for close operation of the equipment to facilitate operators to observe the operating equipment nearby (9) there should be no less than 30mA leakage protection device to ensure the safety of equipment and people;

(10) the control system shall operate at a safe voltage of 24V;

(11) the control system should adopt the industrial control safety interlock protection function, the front door of the equipment box should not be opened before the ground, to prevent the fault caused by the wrong operation; PLC control system, programmable operation, each action can be run independently, and individual actions interlock

(12) at the feeding port, there should be a fence to prevent garbage from being scattered outside the feeding port;

(13) 8mm patterned steel plate shall be used on the upper part of the box to meet the requirements of the large collection vehicle for feeding;

(14) with plasma physical air disinfection, deodorization system and sewage disinfection, deodorization purification system;

(15) sewage discharge system: there is an automatic sewage discharge system

(16) mechanical insurance system: there is a bumper device at the bottom of the box to prevent the box from falling down accidentally when cleaning the foundation pit